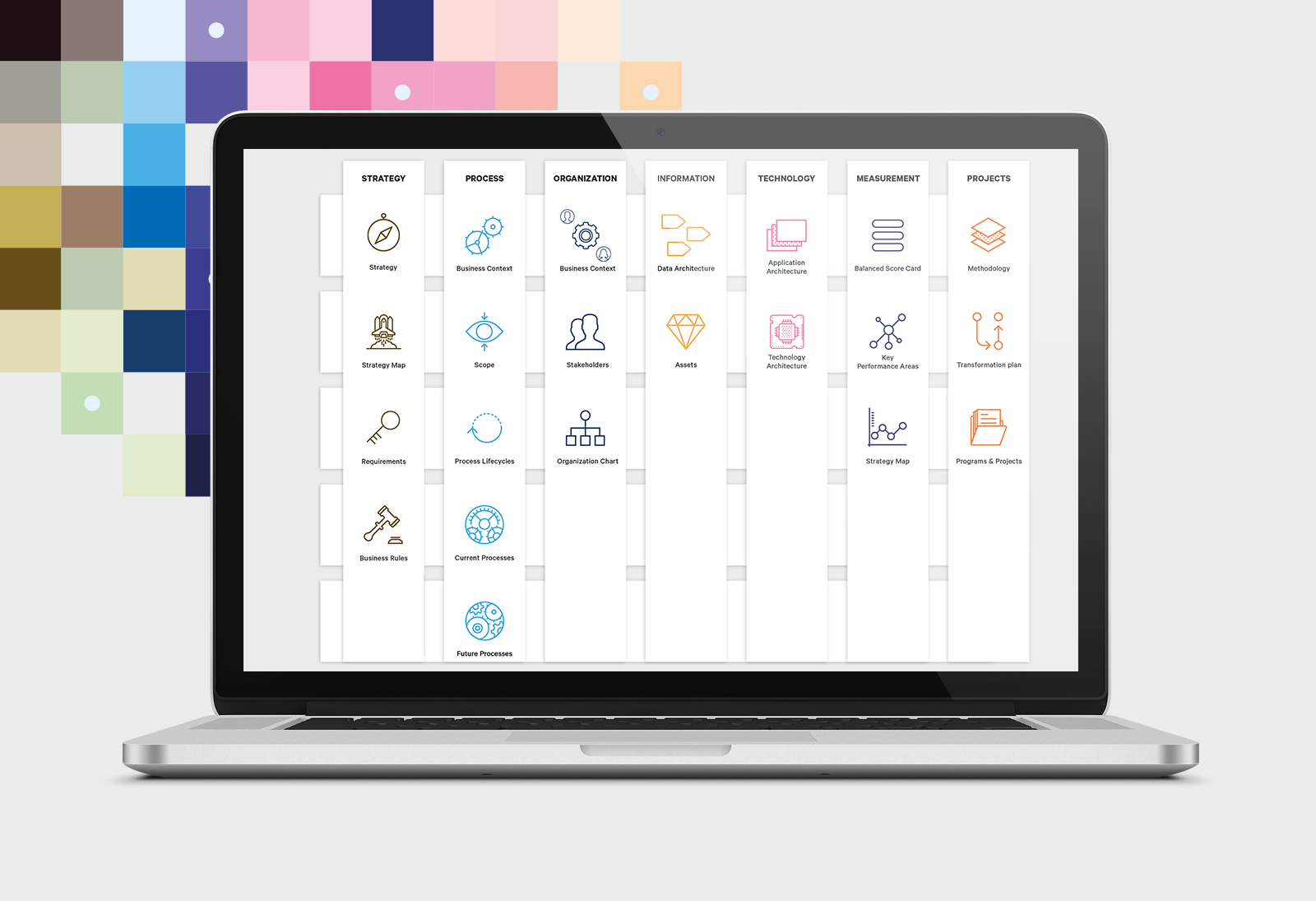

FORTIG’s philosophy is to start with rich content,

not a blank piece-of-paper

Our approach using FORTIG's Methodology guides you

to achieve consistent, high value results quickly.

Initiate & Plan

Appoint a core team. Review FORTIG's Methodology. Design a plan for your asset performance improvement initiative to achieve the intended business outcomes.

Document The Strategy & Set Scope

By documenting your organization's strategic intent for the asset performance improvement initiative, everyone is clear on the intended outcomes: team members, all stakeholders of the asset, the project's sponsor, and the senior management team that he / she reports to and has approved the funding for the initiative.

Setting the scope of your asset performance improvement initiative is important. Everyone involved must know what's in and what's out. Sometimes scope is set by urgency in a high pain-gain area of the business. Sometimes scope is set by internal politics to get buy-in. Sometimes scope is different than what you thought it would be.

A university wanted to replace their legacy computerized maintenance management system (CMMS). They brought in FORTIG to take a business-first rather than a technology-first approach. Initially the scope focused on maintaining assets. Using FORTIG the team understood that maintaining assets meant they had to include an asset management strategy that linked to their business strategy. They realized they had to include procurement, how their storerooms were managed, and the importance of assigning material costs to the assets where they are used. They needed to include commissioning new assets into service, and decommissioning too. FORTIG helped them quickly clarify the streamlined business processes they needed for a well-implemented CMMS and an effective design-build-commission-operate&maintain-decommission organization, develop performance measures to monitor their success, and create a communications strategy to broadcast their results.

Costs are rising exponentially in health care. It doesn't matter how many doctors and nurses you have if a hospital has only two operating rooms. Health care's most expensive assets, the doctors and nurses, become an under-utilized resource. How many types of cotton swabs does a hospital need to stock in inventory? Often it is one type per doctor! This situation kept an executive director of a large health care region up at night. He suspected there were $Millions to be taken out of the health care system but he could't get his hands around the problem.

Using FORTIG, he and his team began to think out-of-the box. They began to look at the supply chain and medical facilities differently. They zeroed on the root cause of rising non-medical costs - bulging inventory and too few operating rooms.

FORTIG opened the door for the team to develop a solution that enabled doctors and nurses to treat more patients and increase revenue, reduce costs, and improve the patient experience. They quantified the $Millions that could be taken out of the health care system without impacting their high quality of medical care. Using FORTIG the health care region gained a true competitive edge.

Analyze & Drive Out Defects

Drill down within the scope. Analyze how you manage your assets today. Do a health check. Perform a Root Cause Analysis and drive out defects. Implement the suggestions for improvement. It's a quick win!

A municipality was struggling with new assets they were suddenly given responsibility to operate-maintain by the design-build part of their organization. They used FORTIG to analyze how assets were commissioned into service. The health check results were profound, highlighting what was not working. The results had a big impact on the team striving for asset performance improvement. They used FORTIG to dive into what was not working about their commissioning process and seek out the root of problems. Then they drove out defects with an improvement program. Next they used FORTIG to adopt a clear, effective commissioning process that involved the operators and maintainers in the design-build phases of new assets. New assets would be designed for reliability and maintainability.

"I've worked here for 35 years. We knew we had problems, but we didn't know what they were. With FORTIG we were able to identify recurring symptoms and get to the root causes of our problems. FORTIG gave us a way to drive out these defects and implement a program of asset performance improvement."

-Director of Custodial Services, Facilities Management, an American University

Design The Solution

Accelerate, adapting FORTIG's rich content to match the way your organization wants to manage its assets. Review the Business Motivation to ensure the strategic intent of the project has been met. Create a portfolio of projects to take your organization from where it is today to where it wants to be in the future using FORTIG. Set targets for the measures for success. Develop a business case for the transformation.

Implement. Monitor and analyze results. Adjust the solution. Begin the cycle again.

The Director of Fleet Performance had a vision to improve reliability across their fleet of vessels. His team had spent several months investigating Condition Based Monitoring technologies, Reliability Centered Maintenance approaches, and new CMMS platforms. But he was frustrated with their lack of real progress. Using FORTIG his team quickly identified the new processes the company would need to implement these three levers for asset performance improvement. They realized they needed a skills assessment and training program to bring their people up to speed to implement this new approach and realize his vision. It became clear that the real business need was capacity, and that reliability was the way to find hidden capacity in their current fleet rather than build new ships. FORTIG helped the team develop a compelling business case. A 1% increase in reliability across their global fleet of vessels gave them a 4-ship capacity therefore saving $400M CapEx.